Concept

再生可能エネルギーを中心としたエネルギー機器分野では業界トップクラスのシェアを持ち、水素エネルギーなど先進技術にも取り組んでいます。

また製造装置分野における技術は業界でも高く評価され、活動の領域は国内のみならず海外へも広がっています。

Service

各部門において機器の開発、製造からメンテナンスまで一貫して行います。

また、地域創生事業として酒蔵やゴルフ場を運営しています。

・太陽光発電システム

・蓄電システム

・エネルギーマネジメントシステム

・蒸着装置/スパッタ装置

・太陽電池リサイクル装置

・FA機器

・真空コンポーネント

・洗浄再生/精密部品製作

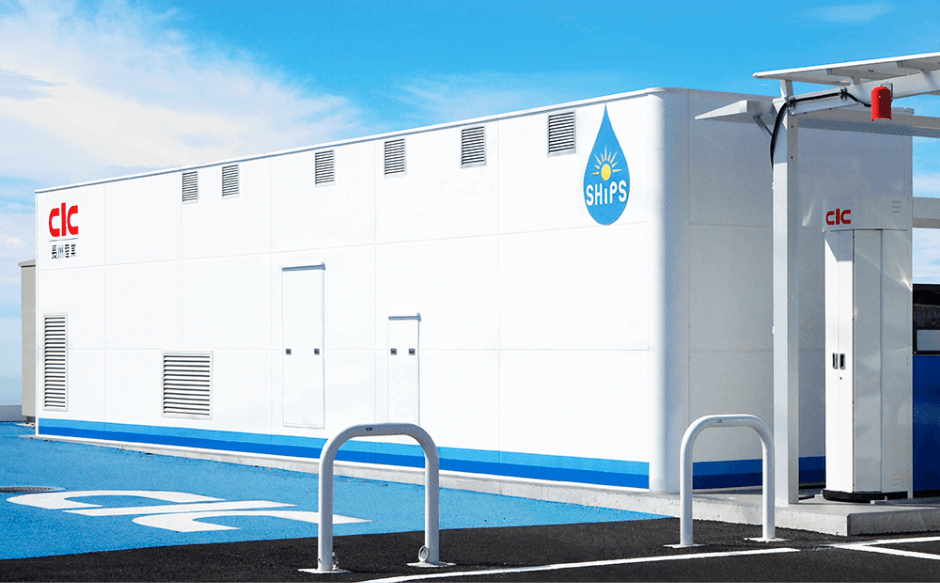

・再生可能エネルギー由来水素ステーション

・バイオマス関連装置

・酒造

・ゴルフ場

Company